Sustainable Recycling Through Renewable Technologies

Creating self-sustaining ecosystems in space with AI-powered resource management

At Space Dust Industries Inc., we're committed to pioneering sustainable recycling practices using renewable technologies. Our vision extends beyond traditional space operations to create self-sustaining ecosystems that will enable humanity's permanent presence in space while maintaining environmental responsibility both on Earth and beyond.

Sustainable practices are not an afterthought; they are integrated into every facet of our operations, from the initial stages of mission planning to spacecraft design, launch, and ongoing mission execution. We understand that the pursuit of knowledge and the expansion of our presence beyond Earth's boundaries must be carried out with the utmost respect for the environment and with a focus on minimizing our ecological footprint.

Life support systems represent the cornerstone of any prolonged space mission, providing the life-sustaining resources necessary for astronauts' survival in the harsh vacuum of space. The pursuit of innovations in life support technology is not just a matter of scientific curiosity; it is a vital aspect of ensuring the safety, sustainability, and cost-effectiveness of our missions beyond Earth's atmosphere.

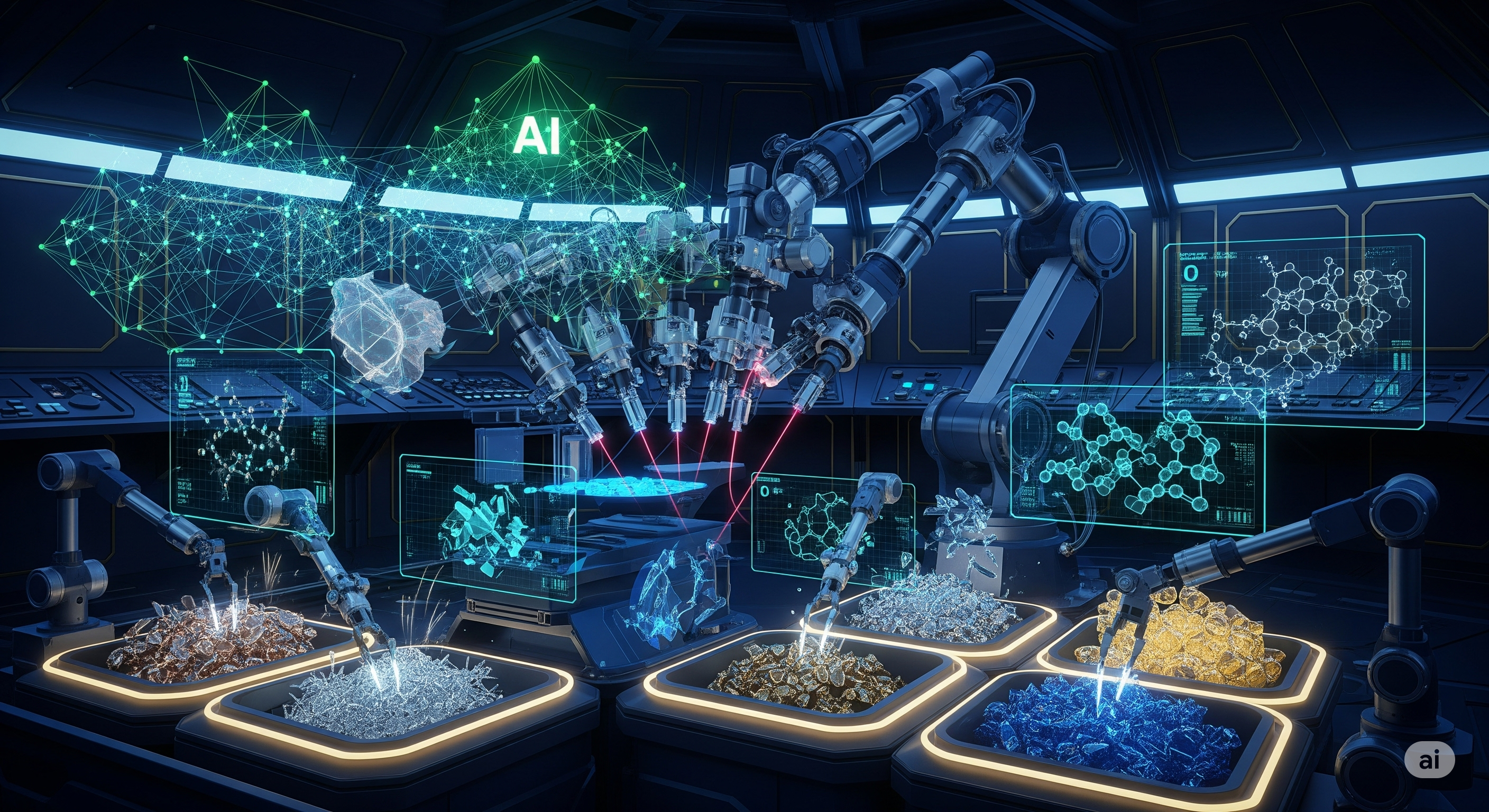

Our innovative space debris processing system transforms hazardous orbital waste into valuable raw materials. Using concentrated solar energy and advanced metallurgical processes, we break down captured debris into its constituent elements, creating a sustainable source of materials for space construction.

This revolutionary approach not only cleans our orbital environment but creates a sustainable source of materials for space construction, reducing the need for expensive Earth-based launches. We're pioneering in recycling space debris using renewable technologies, transforming debris into valuable materials and promoting a circular economy in space.

Our advanced machine learning systems analyze the composition of incoming debris in real-time, automatically sorting materials for optimal recycling efficiency. Neural networks trained on spectroscopic data can identify alloy compositions, contamination levels, and structural integrity.

This ensures maximum resource recovery from every piece of captured space junk. The AI continuously learns from each processing cycle, improving its accuracy and expanding its material recognition capabilities, making our recycling operations increasingly efficient over time.

Harnessing the unlimited power of the sun, our electrolysis systems split water molecules into hydrogen and oxygen - the perfect rocket fuel combination. This process provides a renewable, zero-emission propulsion solution for all our space operations.

By utilizing water from asteroids, comets, or recycled sources, we create a closed-loop fuel system that dramatically reduces mission costs and enables deeper space exploration. This clean and sustainable process utilizes solar power to electrolyze water, generating the fuel needed for propulsion and life support.

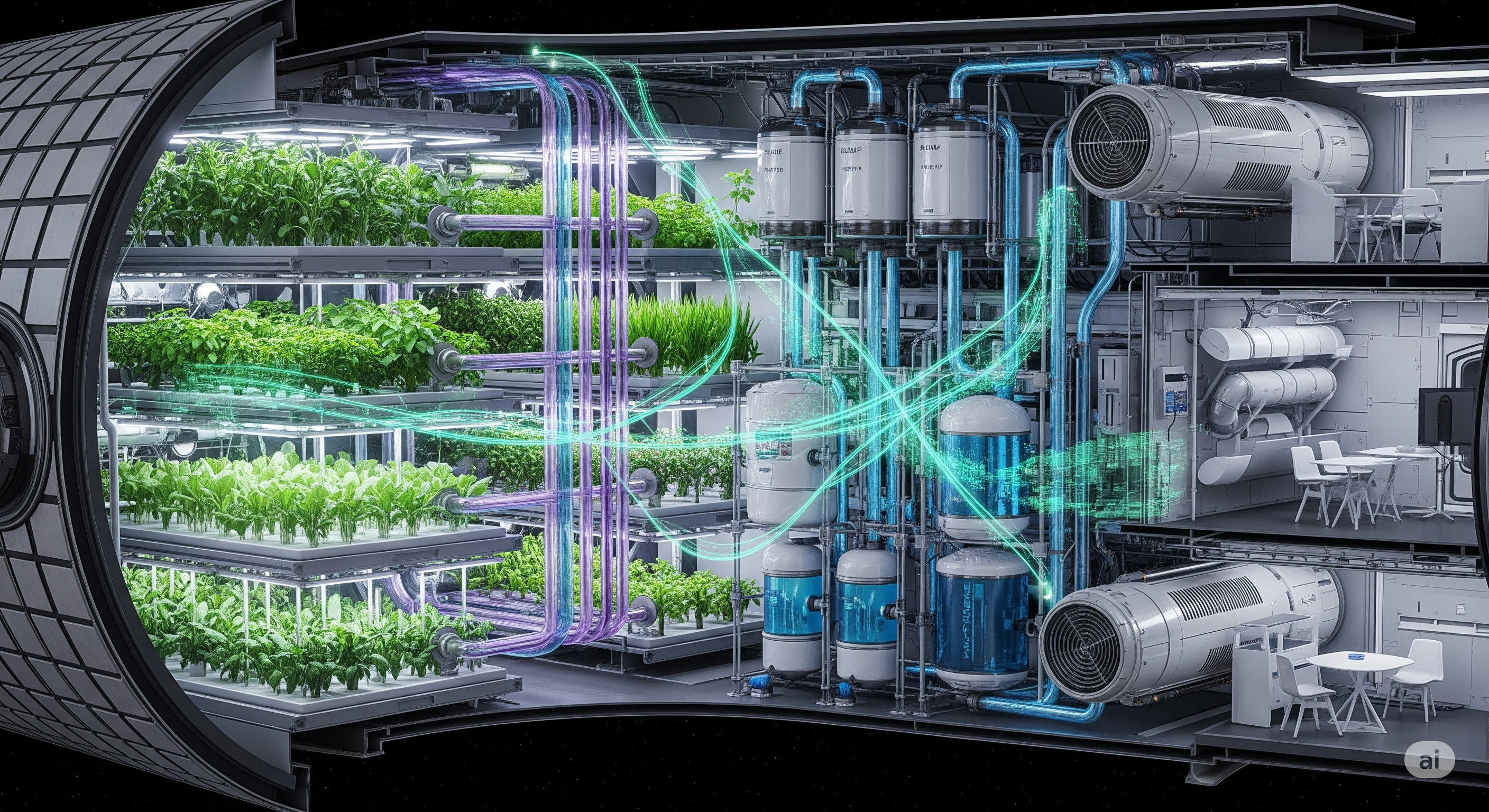

Our advanced life support systems create sustainable environments for long-duration space missions. By recycling air, water, and even waste products, these systems minimize resource consumption and maximize crew safety through closed-loop biological and mechanical processes.

Drawing upon collective knowledge and experience within our organization, we pool our internal resources, expertise, and research efforts to develop cutting-edge closed-loop systems that minimize waste, maximize resource utilization, and ensure the long-term viability of space missions.

Machine learning algorithms continuously monitor system performance, predicting potential failures before they occur. By analyzing patterns in pressure, flow rates, chemical composition, and component wear, our AI ensures uninterrupted life support operation.

This proactive approach has revolutionized space habitat reliability, providing crew safety through intelligent system management. The AI can schedule maintenance during optimal times, order replacement parts before failures, and even guide crew through repair procedures.

Leading the charge in environmentally responsible space exploration, our zero-emission propulsion systems utilize renewable energy sources and clean-burning fuels to minimize the environmental impact of launches and space operations.

From ion drives powered by solar electricity to hydrogen/oxygen rockets producing only water vapor, we're proving that powerful propulsion doesn't require environmental compromise. Our commitment to sustainable practices extends to every aspect of our operation.

Our integrated approach to sustainability creates complete closed-loop ecosystems where every output becomes an input for another system. This biomimetic design philosophy ensures maximum resource efficiency and minimal waste generation.

By connecting water recycling, air revitalization, waste processing, and food production into one seamless system, we achieve unprecedented levels of self-sufficiency for long-duration space missions and permanent habitats.

Beyond basic recycling, our advanced materials processing can break down and reconstitute complex composites, electronics, and specialized alloys. This capability is essential for maintaining and upgrading equipment during long missions without resupply.

Using a combination of chemical, thermal, and mechanical processes, we can recycle virtually any material found in spacecraft or captured debris, transforming waste into valuable resources for construction, repair, and manufacturing.

Our integrated approach to sustainable space technology ensures that humanity's expansion into the cosmos enhances rather than depletes our resources. Through innovative recycling, renewable energy, and intelligent systems, we're creating the foundation for permanent, thriving space communities.

The adoption of recycling initiatives is not only a matter of resource conservation but also a testament to our commitment to responsible space exploration. These initiatives align with the principles of sustainability, self-sufficiency, and environmental stewardship, ensuring that we leave a minimal ecological footprint in the cosmic environments we explore.

By investing in renewable fuel production technologies, we contribute to the long-term sustainability of space exploration. As we venture deeper into the cosmos and explore celestial bodies with the potential for future human habitation, it is imperative that we leave minimal impact on these pristine environments. Our approach to energy systems resonates with the principles of responsible space exploration, ensuring that we preserve and protect the places we visit, just as we do on Earth.

Partner with us to develop the next generation of sustainable space technologies.

From closed-loop life support to zero-emission propulsion, we're creating the systems that will enable humanity's permanent presence in space.

Explore Sustainability Partnerships