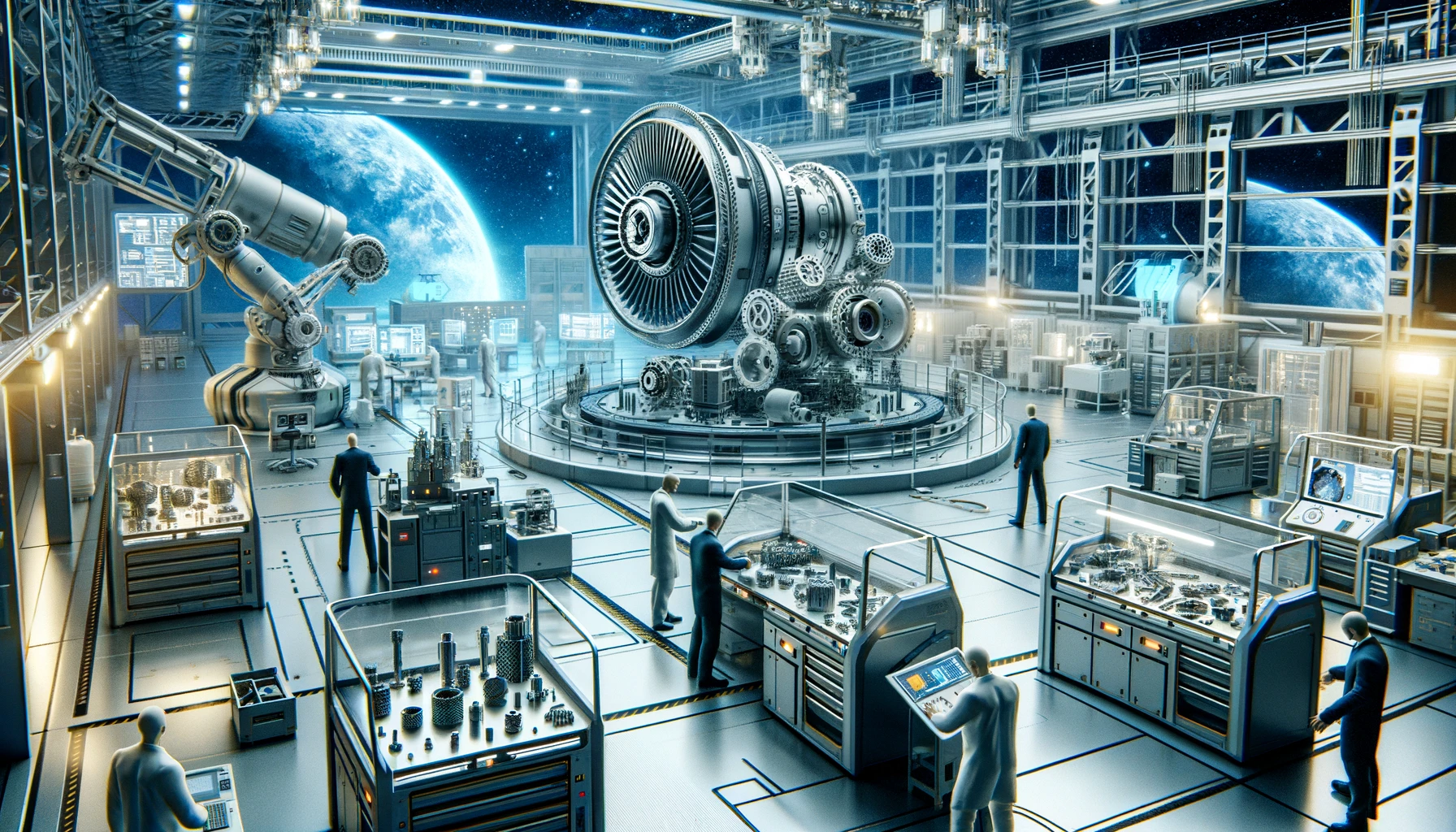

Revolutionizing Space Manufacturing

Advanced 3D printing and AI-powered quality control for the next generation of space components

Additive Manufacturing Division

Pioneering Production Techniques for Space

At Space Dust Industries, we're transforming how components for space missions are produced. Our advanced additive manufacturing processes combine cutting-edge 3D printing technologies with AI-powered quality control to create components that are lighter, stronger, and more reliable than ever before.

From carbon fiber composites to precision metal parts, our manufacturing capabilities enable rapid prototyping, on-demand production, and even in-space fabrication – essential for the future of space exploration. Materials science and manufacturing constitute a pivotal axis of our space missions and operations, representing the very building blocks upon which our ambitions are realized.

Additive manufacturing, often referred to as 3D printing, stands as a revolutionary paradigm shift in the world of manufacturing, particularly in the context of space exploration. This innovative technique has the potential to redefine the way we produce components and structures for space missions, offering precision, flexibility, and efficiency that traditional manufacturing methods cannot match.

Our advanced carbon fiber manufacturing process creates components that are up to 70% lighter than traditional materials while maintaining superior strength. These parts are essential for reducing launch costs and improving spacecraft performance.

We utilize automated fiber placement technology combined with precision molding to create complex geometries impossible with traditional manufacturing methods. Each component undergoes rigorous testing to ensure it meets the extreme demands of space environments.

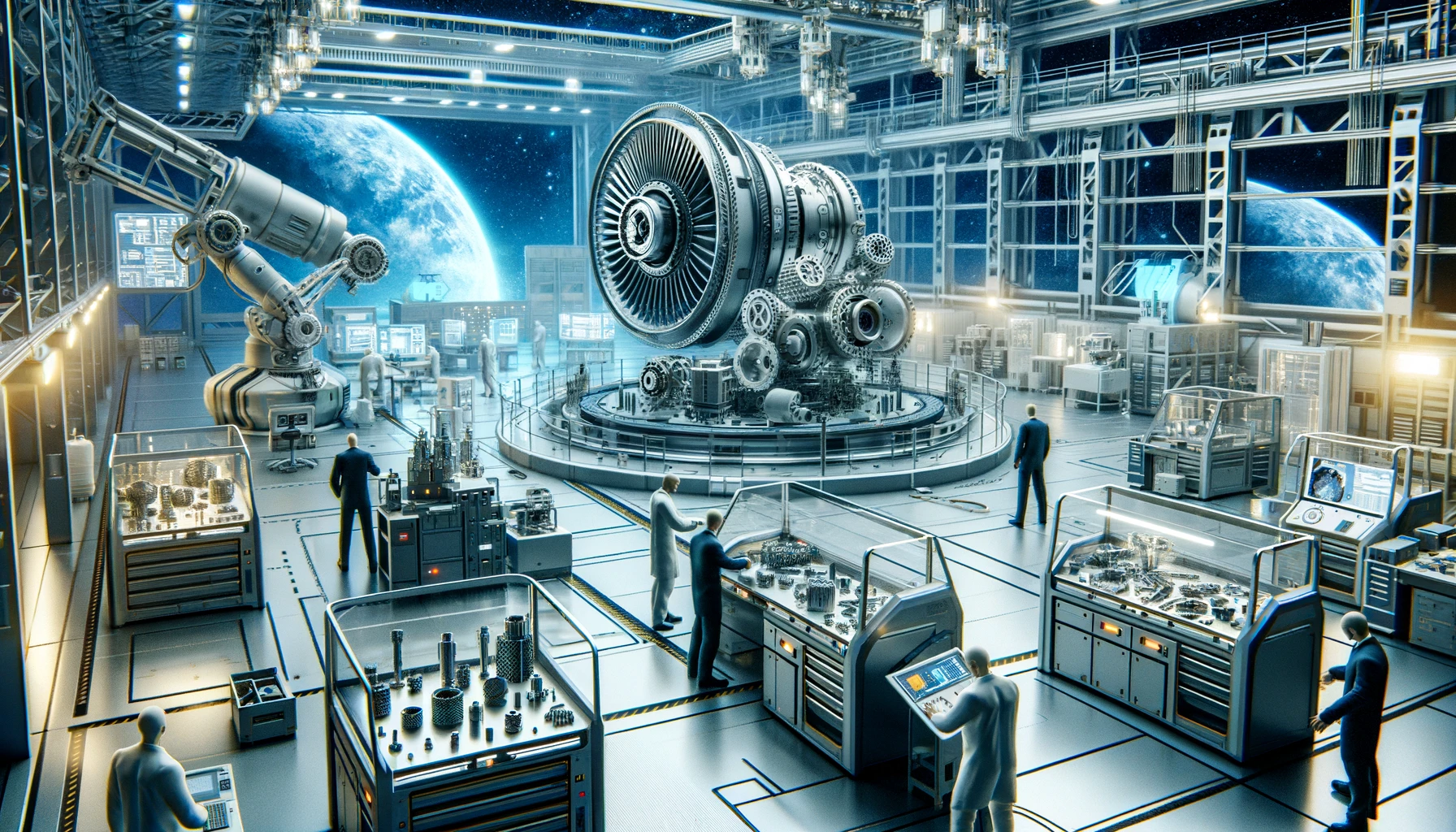

Our vacuum laser sintering technology enables the creation of complex metal components with internal geometries impossible to achieve through traditional manufacturing. This process is crucial for producing lightweight yet strong parts for spacecraft propulsion systems and structural components.

Operating in a controlled vacuum environment eliminates oxidation and contamination, resulting in parts with exceptional purity and structural integrity. We work with titanium alloys, aluminum, Inconel, and specialized space-grade materials.

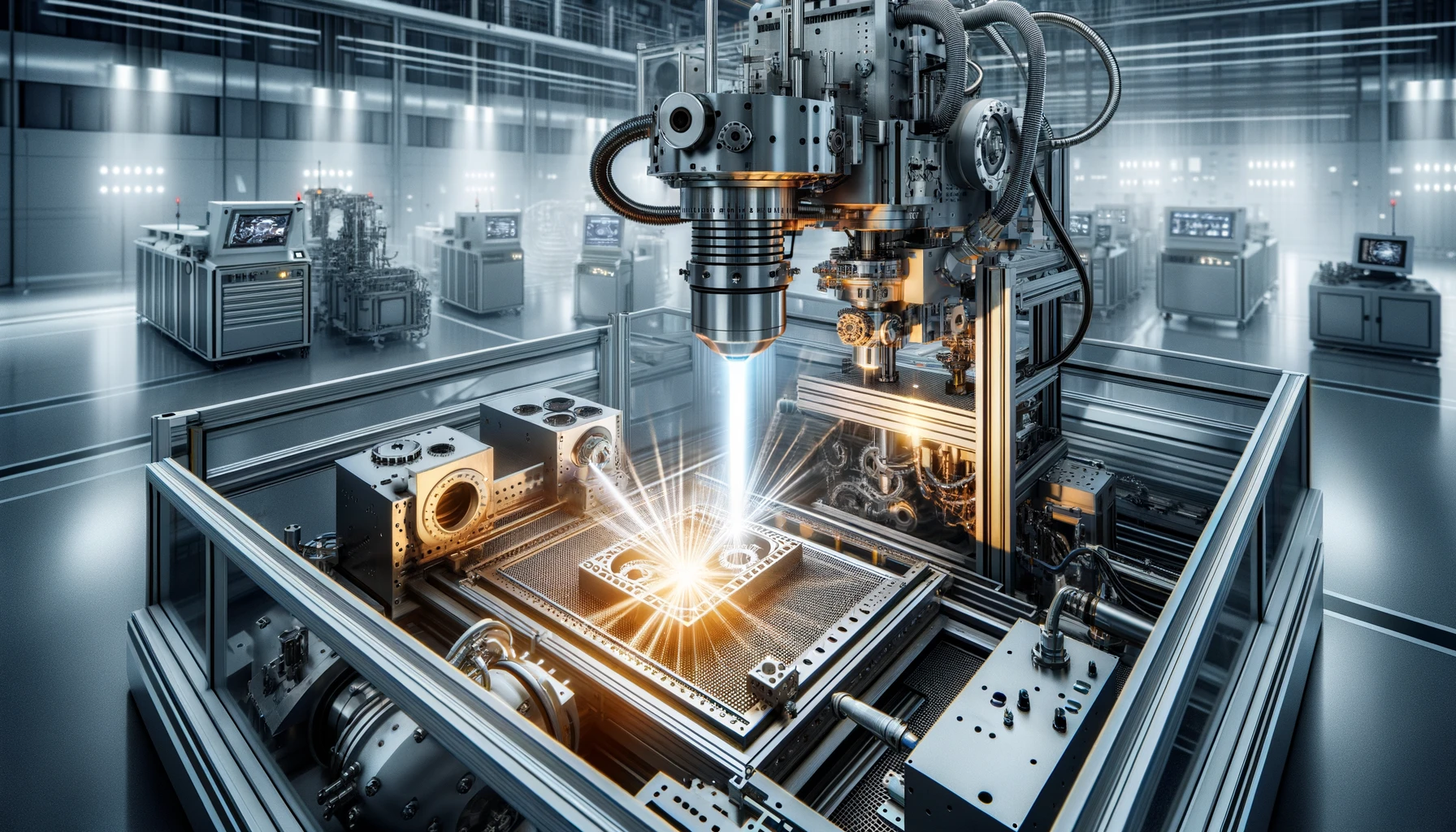

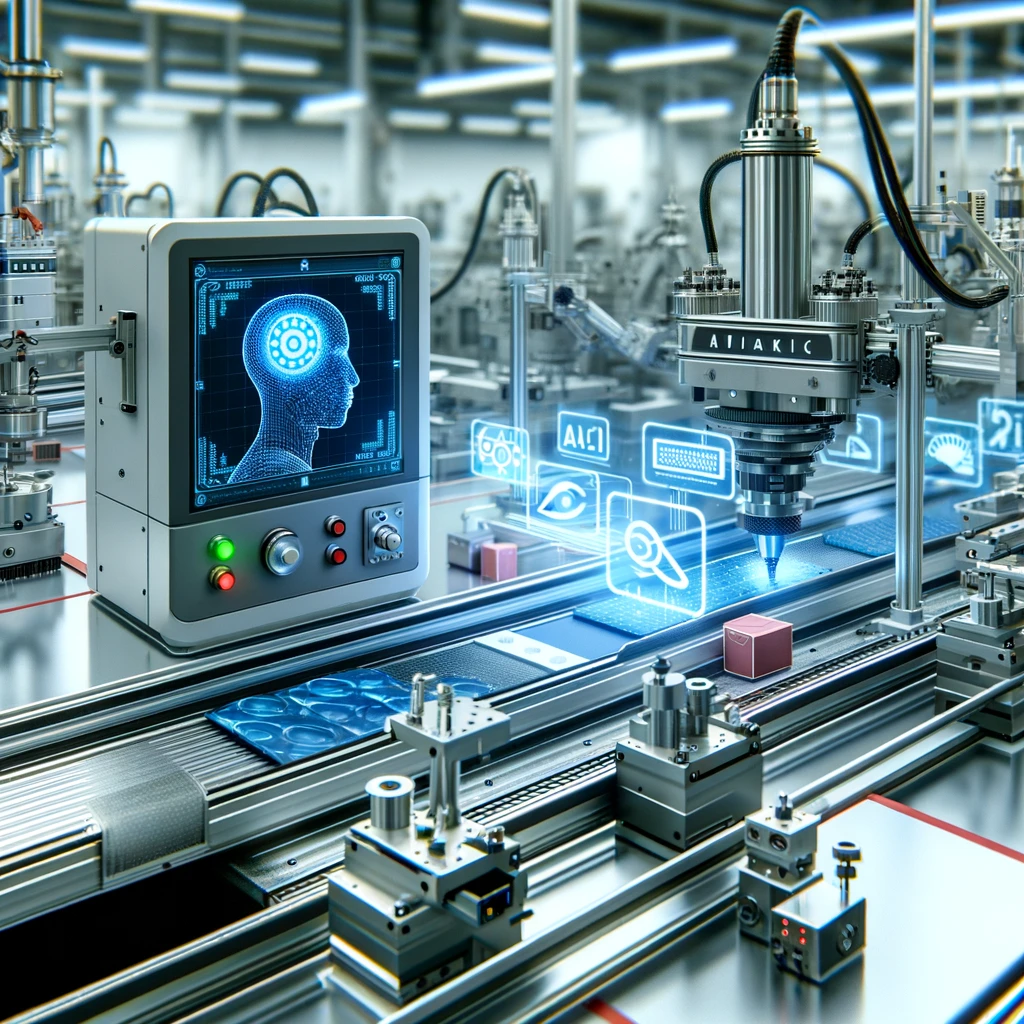

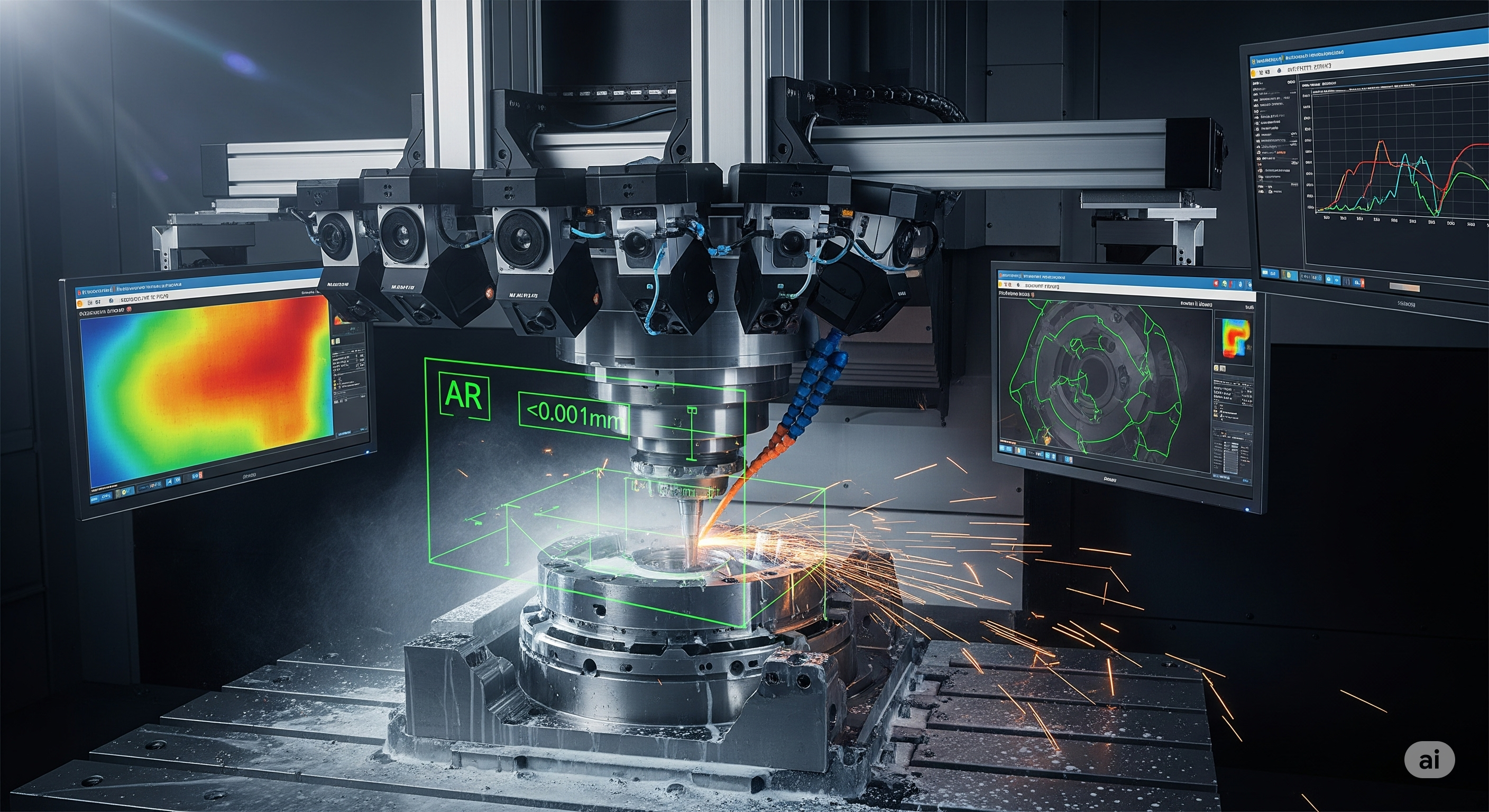

Our integrated AI and Automatic Optical Inspection (AOI) system represents a quantum leap in manufacturing quality control. Using advanced machine learning algorithms trained on millions of component images, our system detects defects invisible to the human eye.

The integration of artificial intelligence into our materials science and manufacturing processes represents a transformative leap forward. AI-based quality control not only enhances our efficiency and precision but also reinforces our commitment to the safety and success of space missions.

Beyond traditional inspection, our computer vision systems provide real-time quality control during the manufacturing process itself. Multiple high-resolution cameras and sensors monitor every stage of production, instantly detecting and correcting deviations.

The system uses deep learning neural networks to understand complex patterns and predict potential failures before they occur. This predictive quality control reduces waste and ensures consistent output quality across all production runs.

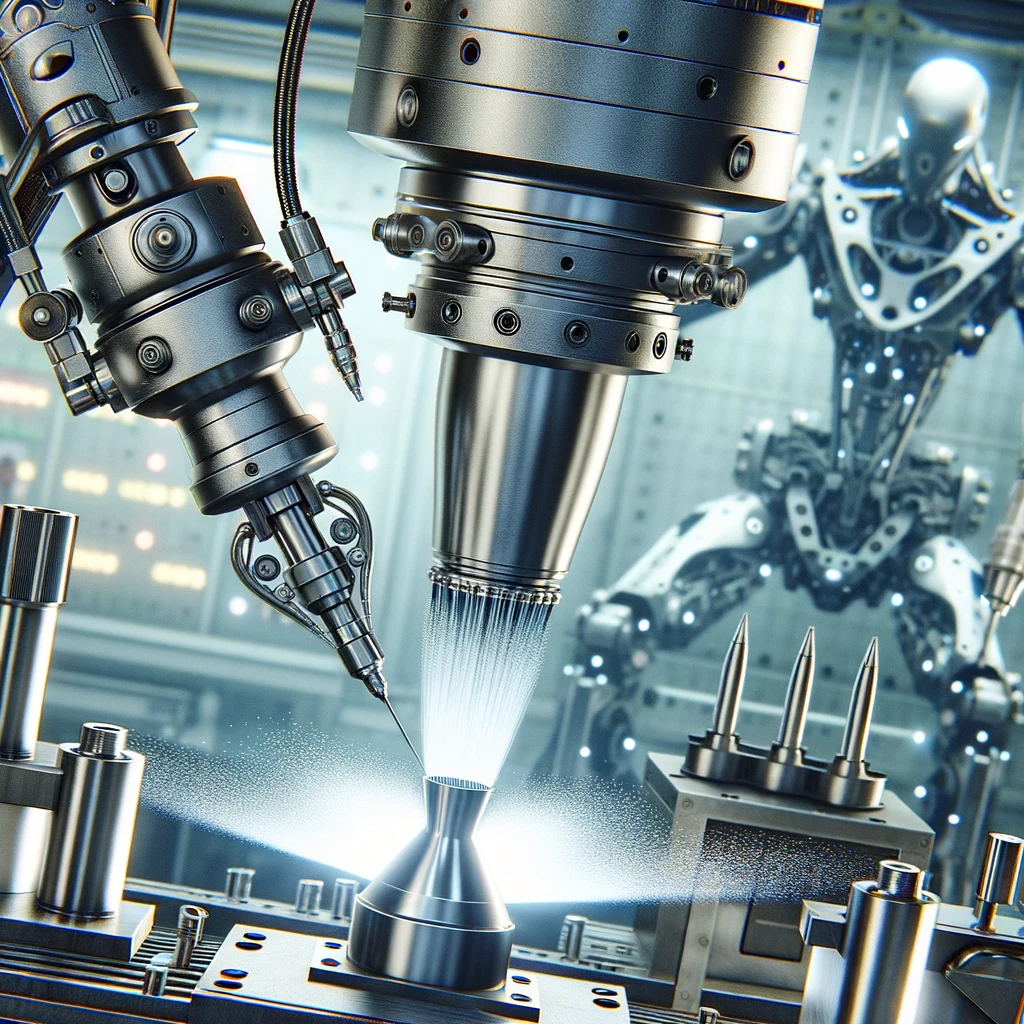

Our revolutionary cold spray technology enables precise metal deposition for rocket nozzle fabrication and repair. This process accelerates metal particles to supersonic speeds, creating dense, high-strength coatings and structures without the heat damage of traditional welding.

Cold spray in supersonic nozzle fabrication represents another pioneering application of advanced manufacturing. By utilizing this technique, we can add precise layers of metal to supersonic nozzles, enhancing their performance and durability.

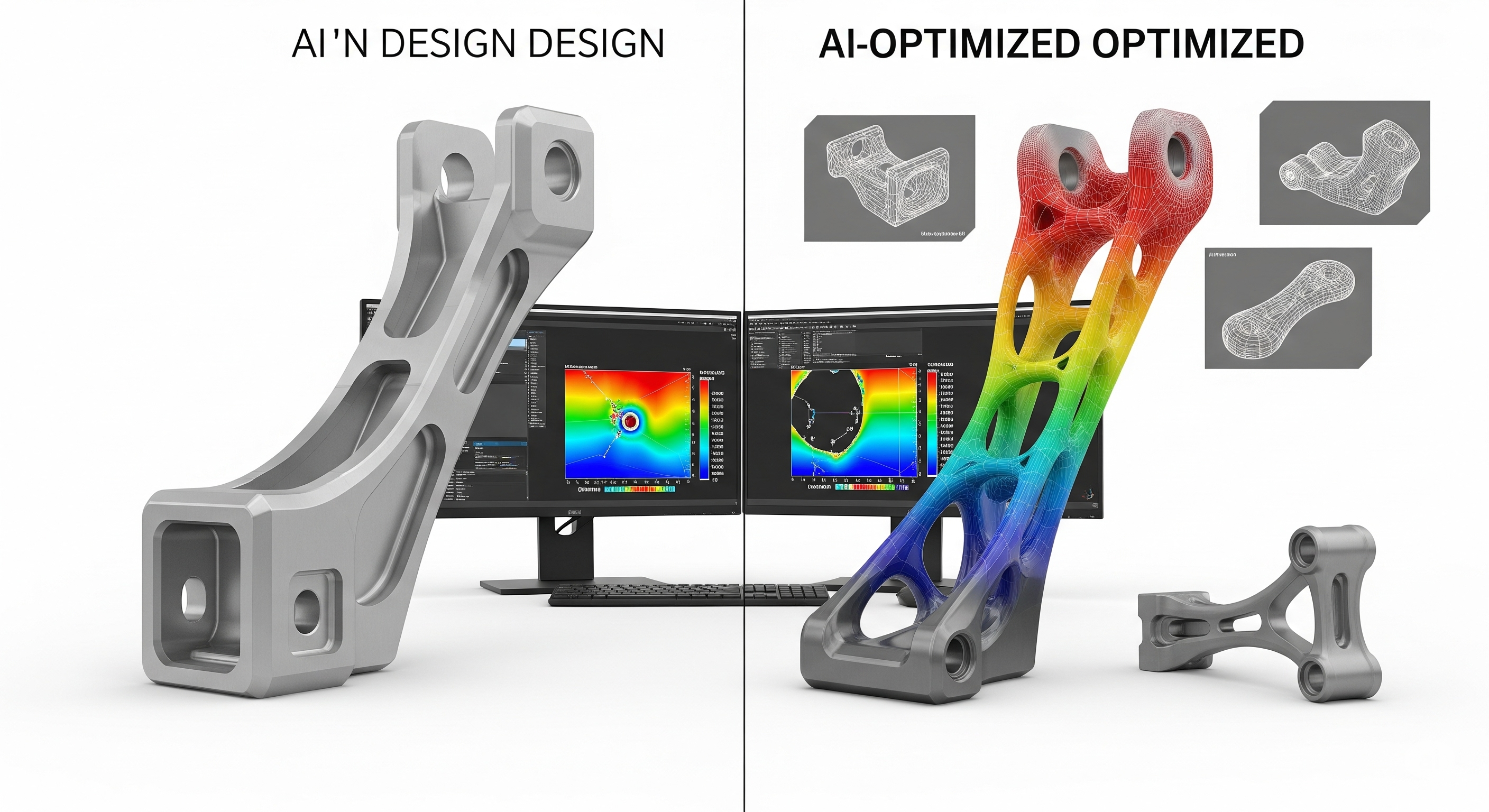

Our generative design AI revolutionizes how spacecraft components are conceived. By inputting performance requirements and constraints, the AI generates thousands of optimized designs that human engineers might never imagine.

The system considers factors like weight, stress distribution, thermal properties, and manufacturing constraints to create organic, efficient structures. These AI-designed components often achieve 40-60% weight reduction while improving performance.

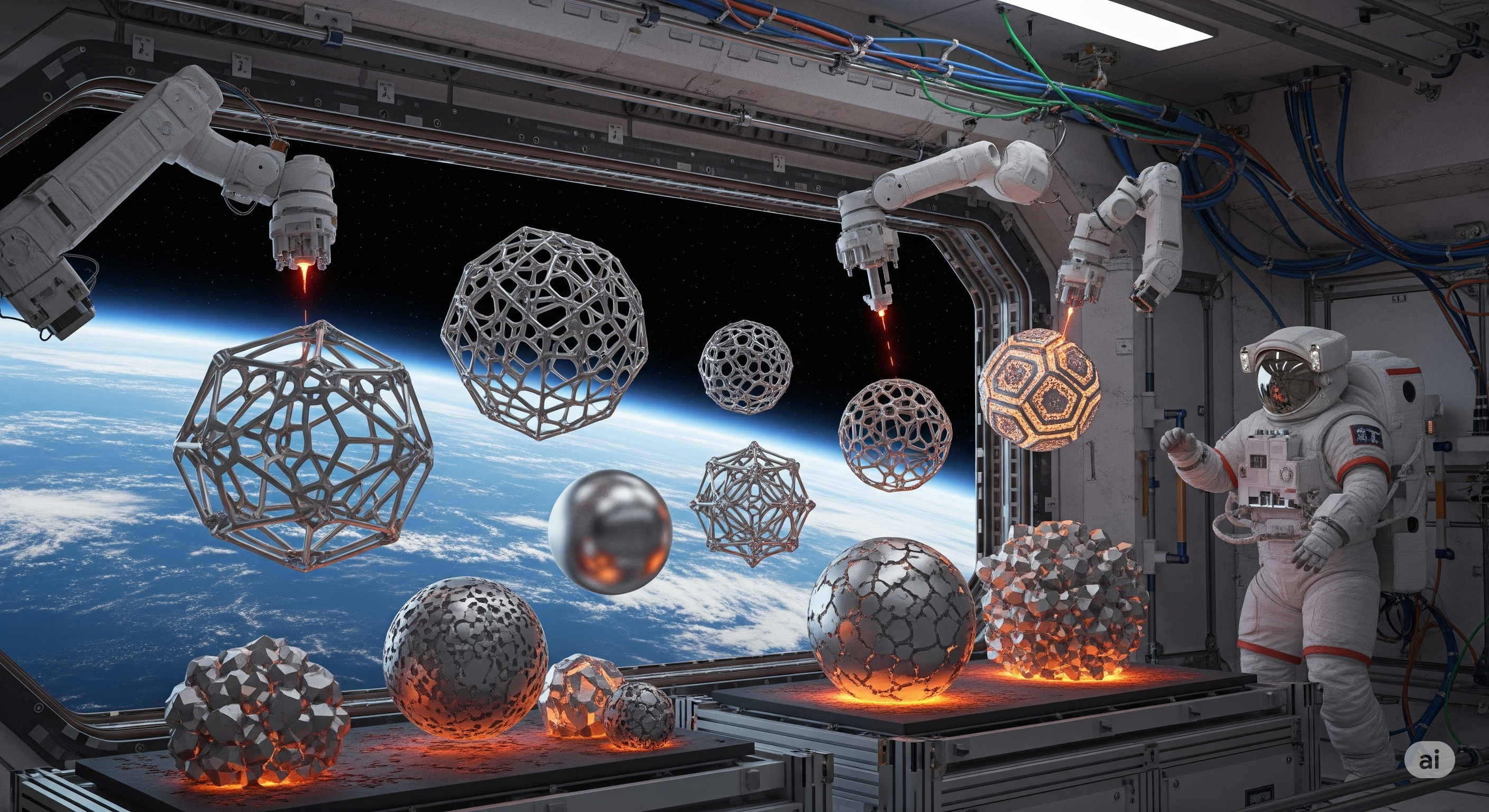

The unique microgravity environment of space offers unprecedented opportunities for manufacturing. In space, we can create materials and structures impossible to produce on Earth, including ultra-pure crystals, advanced alloys, and perfectly spherical components.

Our in-space manufacturing systems are designed to operate autonomously, producing replacement parts, tools, and even large structural components on-demand, dramatically reducing the need for Earth-based resupply missions.

Our materials research initiatives are laser-focused on overcoming the challenges posed by the harsh conditions of space. We develop materials that exhibit radiation resistance, thermal stability, and durability in the face of cosmic forces.

From self-healing polymers that can repair micrometeorite damage to ultra-lightweight aerogels for thermal insulation, our advanced materials push the boundaries of what's possible in space engineering.

Our commitment to advanced manufacturing techniques, with a particular emphasis on 3D printing, reflects our vision for the future of space exploration. Through the application of these innovative technologies, we are poised to revolutionize how space mission components are designed, produced, and maintained.

The advantages of precision, flexibility, and sustainability offered by additive manufacturing in space align perfectly with our mission to explore, innovate, and push the boundaries of human understanding in the vast cosmos. By implementing advanced manufacturing techniques, particularly 3D printing, we aim to revolutionize the way space mission components are designed, produced, and maintained.

One of the most significant advantages of in-space 3D printing is its potential to reduce reliance on Earth-based resupply missions. Traditional space missions necessitate the transportation of spare parts and tools from Earth, a costly and logistically challenging endeavor. Additive manufacturing in space mitigates this reliance, as we can produce mission-critical components on-site, when and where they are needed.

Our advanced manufacturing capabilities can transform your space mission components from concept to reality with unprecedented speed and precision.

Partner with us to access cutting-edge 3D printing, AI quality control, and materials innovation.

Start Your Manufacturing Project