Extracting Tomorrow's Resources Today

Pioneering sustainable resource extraction from near-Earth asteroids

Asteroid Mining Operations

Harnessing Space Resources for Humanity's Future

Space Dust Industries is at the forefront of asteroid mining technology, developing innovative systems for resource extraction, processing, and utilization in space. Our integrated approach combines cutting-edge robotics, AI-driven optimization, and sustainable practices to unlock the vast mineral wealth of our solar system.

Asteroid mining is a frontier of space exploration with the potential to revolutionize our approach to resource utilization beyond Earth. We are actively conducting comprehensive research and development efforts aimed at unlocking the vast mineral and resource wealth found in near-Earth asteroids. These celestial bodies are not only scientifically intriguing but also hold the promise of supplying essential materials for future space missions.

The potential impact of asteroid mining on space exploration is profound. By harnessing the abundant resources present in near-Earth asteroids, we can reduce our reliance on Earth-based supplies, lower the cost of space missions, and enhance our capability for long-duration missions. Moreover, asteroid mining aligns with the principles of sustainability, as it offers a pathway to resource utilization that minimizes the environmental impact on our home planet.

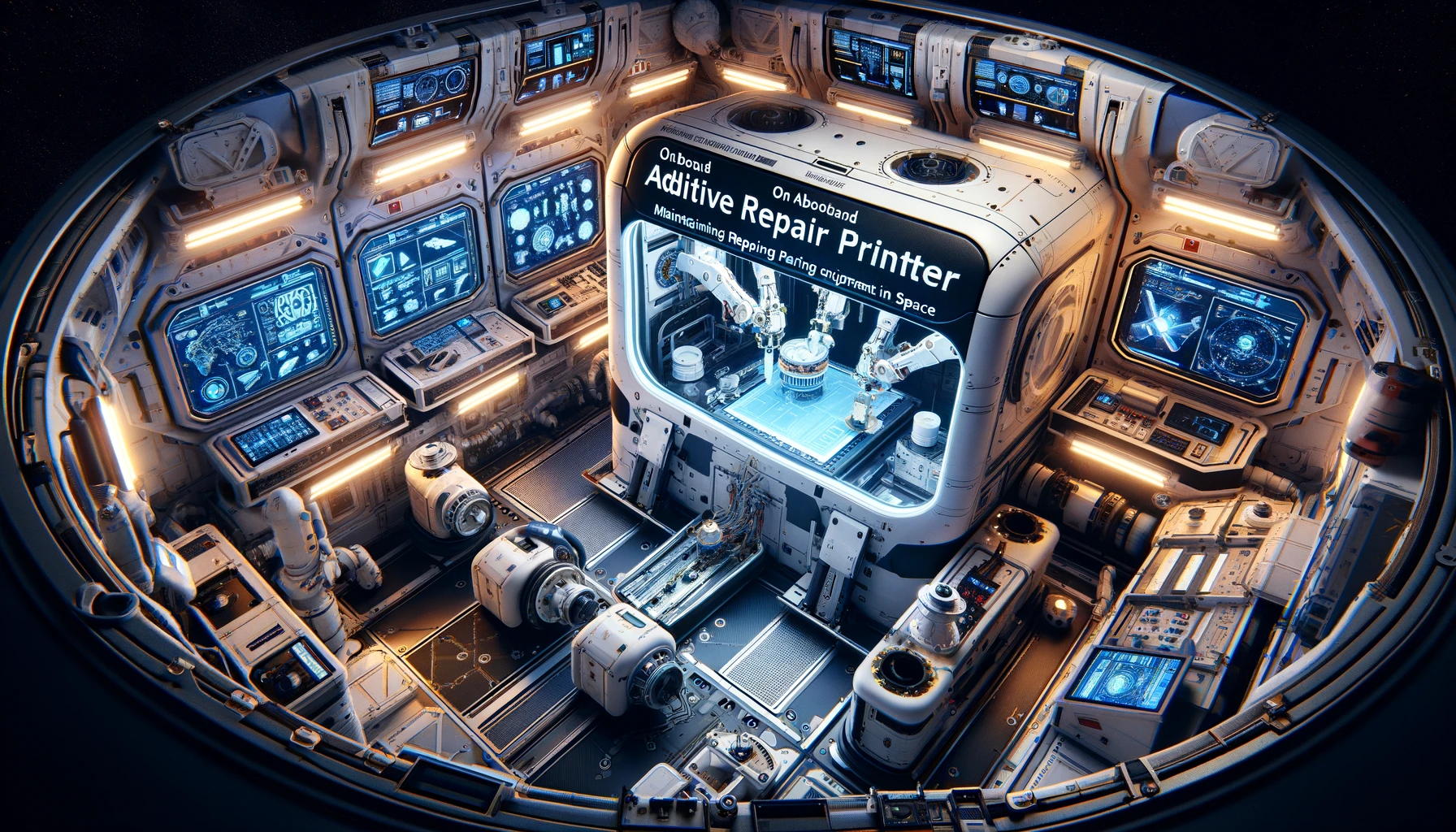

Our spacecraft are equipped with advanced 3D printing systems capable of manufacturing replacement parts and tools on-demand. This revolutionary capability ensures continuous operation during long-duration mining missions, eliminating dependency on Earth-based resupply.

The onboard additive repair printer represents a paradigm shift in space operations. When technical issues arise during a mission, these printers enable us to fabricate replacement parts and components, reducing reliance on Earth-based resupply missions and enhancing mission autonomy.

Converting water ice found on asteroids into rocket fuel through solar-powered electrolysis. This closed-loop system produces hydrogen and oxygen propellants, enabling extended missions and reducing launch mass requirements from Earth.

By utilizing water from asteroids, comets, or recycled sources, we create a closed-loop fuel system that dramatically reduces mission costs and enables deeper space exploration. This technology is crucial for establishing sustainable mining operations far from Earth.

Revolutionary material transport system using electromagnetic acceleration to launch mined resources to orbital processing stations. The LAC system enables efficient, continuous transfer of raw materials without traditional rocket propulsion.

This innovative technology has revolutionized the way we handle space logistics and has far-reaching implications for the efficiency and sustainability of our missions. It offers a streamlined and highly efficient means of transporting bulk materials.

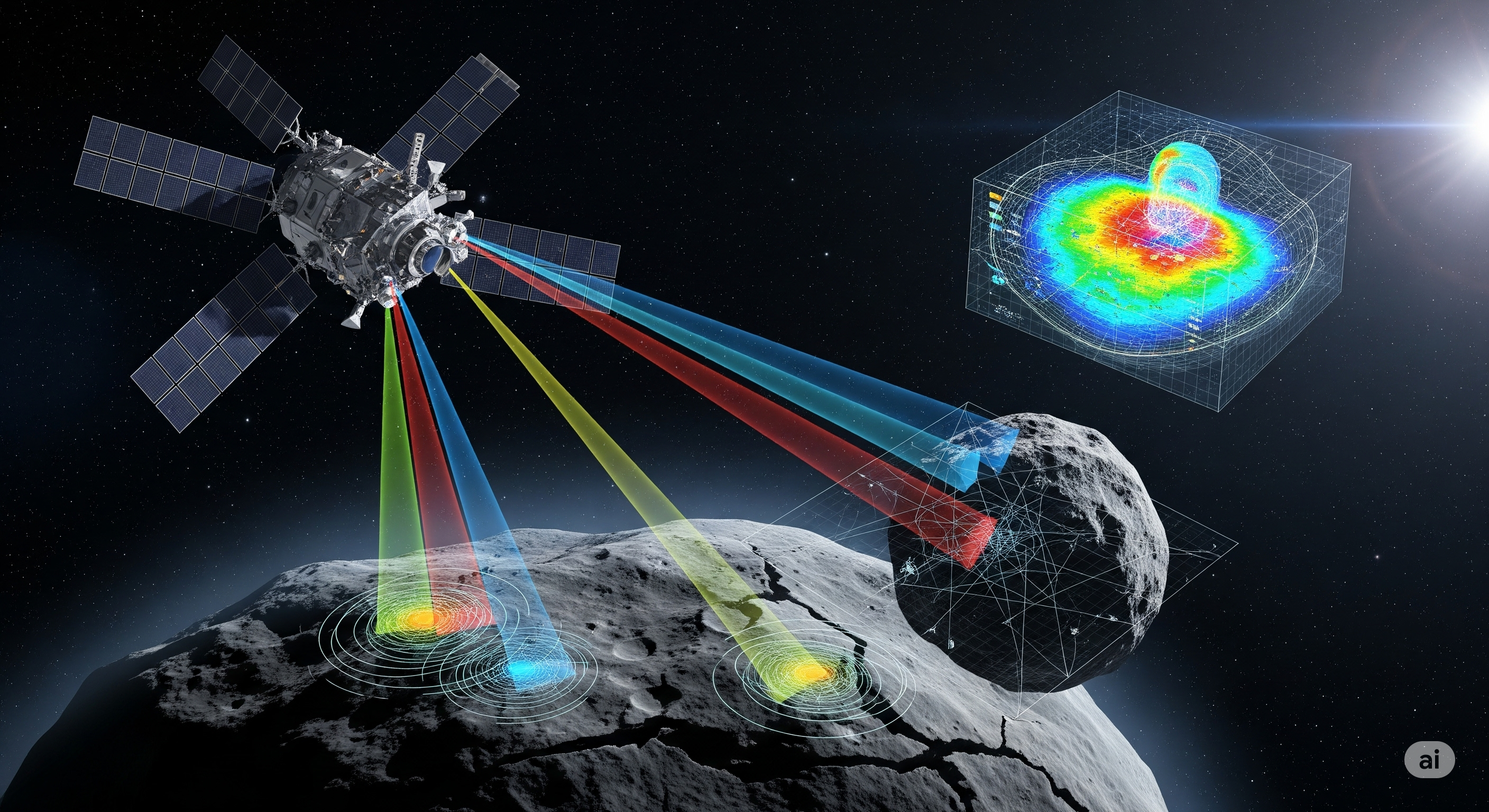

Deep learning algorithms analyze spectroscopic data to identify optimal mining locations and predict mineral concentrations. Our AI systems continuously optimize extraction strategies, maximizing yield while minimizing energy consumption.

The AI's ability to process vast amounts of geological data and identify patterns invisible to human analysis has increased our mining efficiency, while reducing operational costs and environmental impact.

Utilizing concentrated solar energy to process and forge extracted precious metals into aerodynamic shapes for Earth return. This zero-emission processing method creates standardized ingots designed for atmospheric reentry.

Our solar forging technology represents a breakthrough in space-based materials processing, eliminating the need for traditional fuel-based heating while achieving temperatures exceeding 3,000°C through concentrated solar power.

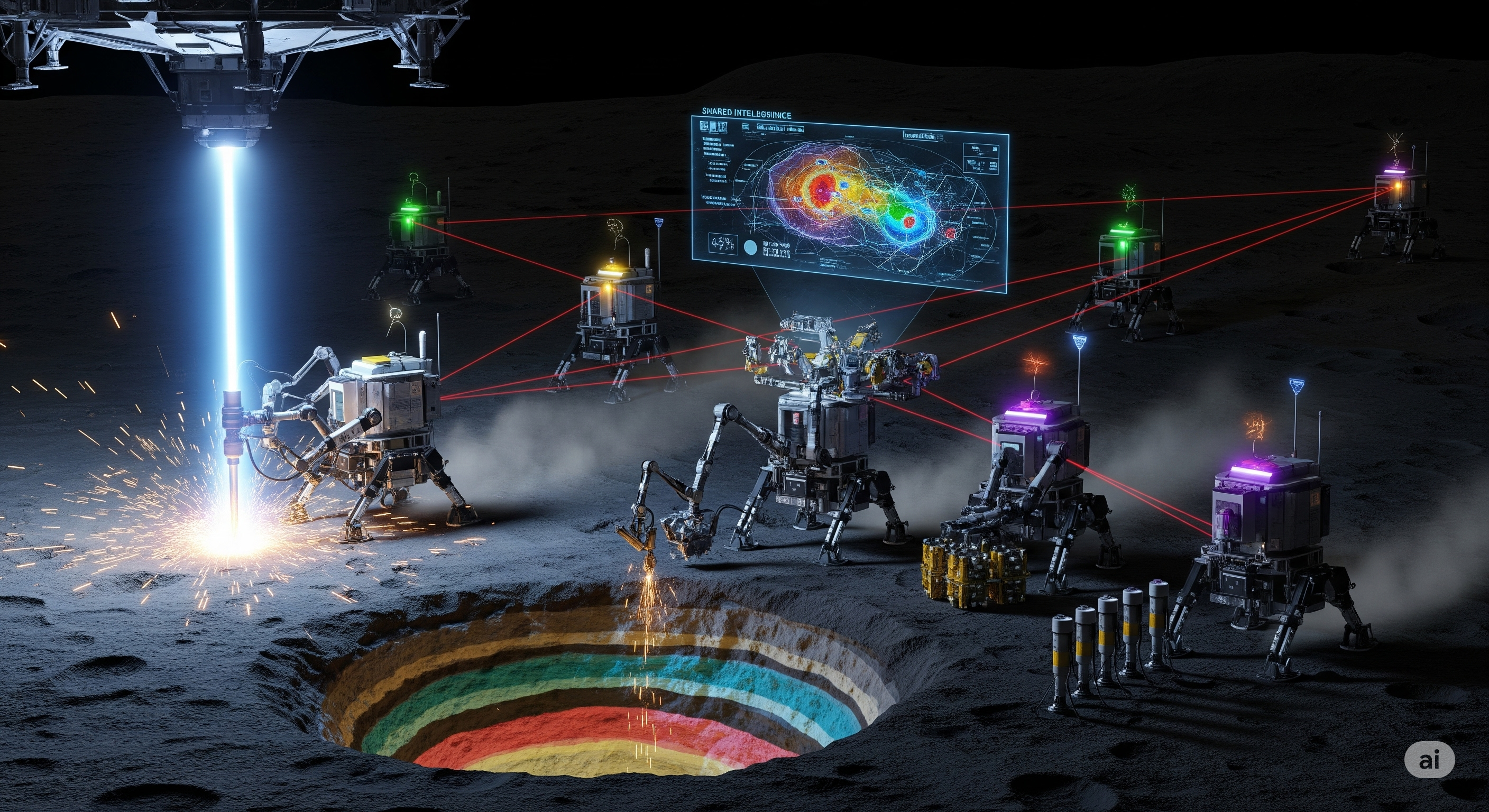

Fully autonomous robotic systems powered by reinforcement learning algorithms that adapt to changing asteroid conditions. These systems operate independently for months, making real-time decisions to optimize extraction efficiency.

Our swarm robotics approach allows multiple units to collaborate, sharing data and coordinating efforts to tackle complex mining challenges. Each robot can operate independently or as part of a coordinated team.

Our prospecting technology combines multiple sensing modalities to create comprehensive maps of asteroid composition before mining begins. This reduces risk and maximizes the efficiency of our extraction operations.

Using a combination of radar, spectroscopy, and gravitational analysis, we can identify the most valuable targets and plan optimal extraction strategies before committing resources to mining operations.

Our orbital processing facilities transform raw asteroid materials into refined products ready for use in space construction or return to Earth. These facilities operate autonomously, processing tons of material daily.

By processing materials in space, we eliminate the need to transport raw ore, dramatically reducing transportation costs and enabling the creation of space-based supply chains for future missions.

A single metallic asteroid can contain more platinum than has ever been mined on Earth, along with vast quantities of iron, nickel, cobalt, and rare earth elements essential for modern technology. Our mining operations target these resource-rich bodies, with some asteroids valued at quintillions of dollars.

Beyond the economic value, asteroid mining provides the raw materials necessary for space industrialization. Iron for construction, water for fuel and life support, and rare metals for electronics can all be sourced from asteroids, enabling sustainable space development without depleting Earth's resources.

Our R&D initiatives in asteroid mining are driven by a vision of sustainability and self-sufficiency in space. The development of advanced technologies for prospecting, extraction, and processing of asteroid resources is central to our mission. These technologies encompass robotic spacecraft, specialized mining equipment, and resource processing systems tailored to the unique challenges of the asteroid environment.

Partner with Space Dust Industries to access the limitless mineral wealth of our solar system.

From prospecting to processing, we provide complete asteroid mining solutions for the new space economy.

Start Your Mining Mission